Earlier this week, additive building firm Alquist and Habitat for Humanity formally handed over the keys to the brand new proprietor of an in any other case ordinary-looking three-bedroom single-family house in Williamsburg, Virginia. Regardless of appearances, nonetheless, that constructing was lately accomplished as the primary Habitat undertaking on the East Coast to be constructed with assistance from a large 3D printer. The 1,200-square abode at 129 Forest Heights Highway in Williamsburg’s Ewell neighborhood can be being billed because the world’s first 3D-printed owner-occupied house.

Regardless of the spectacular superlative, the undertaking, spearheaded by the Newport Information-headquartered Habitat for Humanity Peninsula and Higher Williamsburg in partnership with Alquist, isn’t technically the primary 3D-printed Habitat undertaking in the USA. Introduced simply weeks forward of the Williamsburg undertaking this previous summer season was a 1,738-square-foot Habitat dwelling constructed with a gantry-style Construct on Demand Printer (BOD 2) in Tempe, Arizona. (Alquist isn’t concerned with that Habitat Central Arizona-led endeavor.) In complete, it took 22 hours to print the Williamsburg Habitat house, slashing the usual building schedule by roughly 4 weeks.

The Williamsburg undertaking’s new proprietor is April, a first-time home-owner who will likely be residing within the 3D-printed digs together with her 13-year-old son. As beforehand detailed, April has labored full-time as a laundry facility supervisor at an area resort for a number of years however receives an earnings that’s lower than 80 % of the realm median earnings, placing conventional homeownership out of attain.

“Going ahead, her month-to-month mortgage funds will likely be not more than 30 % of her earnings, together with her actual property taxes and home-owner’s insurance coverage,” elaborated Janet V. Inexperienced, CEO for Habitat for Humanity Peninsula and Higher Williamsburg, in a press release launched over the summer season when the undertaking was first introduced. “As soon as the home building is full, she’s going to shut on her new house with an area lawyer and repay her no-interest mortgage to us right here on the native Habitat, illustrating Habitat for Humanity’s goal to present households a hand up quite than a handout.”

As required by the Habitat Homebuyer Program, April logged a complete of 300 sweat fairness or volunteer hours at each the development website and at an area Habitat ReStore over the previous a number of months. On the December 21 dedication and ribbon-cutting ceremony attended by quite a few native and state officers and their representatives, April instructed the assembled crowd: “That is all for my son. In the event you really imagine in one thing, hold making an attempt and you are able to do it.”

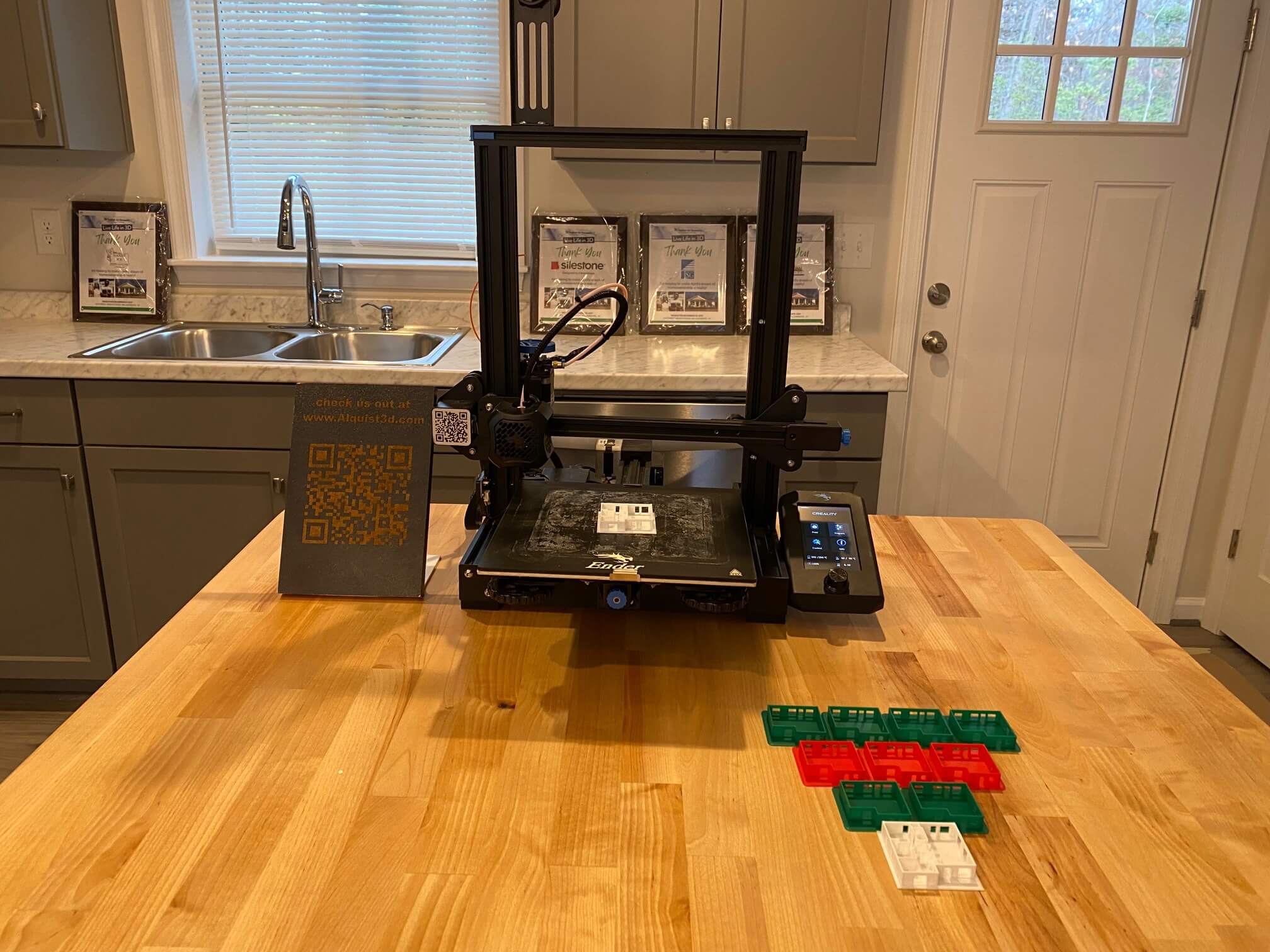

As soon as April is settled into the EarthCraft-certified, tornado-resistant house, she’ll take pleasure in further financial savings because of a proprietary, Raspberry Pi-based monitoring system developed by Virginia Tech that, amongst different issues, will assist to optimize vitality consumption, aided by the thermal properties of the concrete construction itself. There are additionally plans to outfit the house with photo voltaic panels. April has additionally obtained a particular (and much much less colossal) 3D printer from Alquist that can be utilized for primary family repairs and transforming jobs as wanted.

Established in 2020 by Zachary Mannheimer with the aim of bringing large-scale 3D-printing know-how to inexpensive housing-strapped swaths of rural America, Alquist has future tasks deliberate for outdoor of Virginia, the place the corporate has additionally teamed with Virginia Tech to assemble America’s first 3D-printed, public-private partnership-funded house in Richmond’s Midlothian neighborhood. At this week’s dedication ceremony, Mannheimer referred to Virginia as “the chief in 3D printing house building, arms down.”

Past Virginia, Alquist has its sights set on rural communities in Arkansas, California, Iowa, North Dakota, and Pennsylvania for 3D printer-based homebuilding efforts that may be carried out extra swiftly and at a lesser value than standard stick-built building. These tasks will likely be realized with companion firm Atlas Group Studios, which is described as a “wholly unbiased placemaking and financial growth group” and was additionally based by Mannheimer. Apparently, Mannheimer doesn’t come from a standard building or tech background—actually, removed from it. Now primarily based in Des Moines, Iowa, the Pennsylvania-reared erstwhile New Yorker’s roots are on the planet of off-Broadway theater, which is smart given the dramaturgical roots of his newest enterprise’s title.